In environments where equipment is exposed to harsh conditions, precision and durability are essential. Membrane switches have become the go-to solution for industries that require reliable and long-lasting control systems. From rugged industrial machines to critical medical devices, membrane switches offer a host of benefits that make them the ideal choice for environments where durability, reliability, and seamless user experience are non-negotiable.

Membrane switches are thin, flexible, and highly customizable, providing a user-friendly interface that integrates with complex devices. This blog explores the core features of durable membrane switches and why they have become indispensable in industrial and medical applications.

1. Durability in Harsh Environments: Industrial-Grade Strength

Industrial environments can be unforgiving. Machines in factories, processing plants, and heavy-duty operations are often exposed to dust, chemicals, moisture, and extreme temperatures. Durable membrane switches are built to withstand these conditions, ensuring that machinery continues to operate smoothly, even under duress.

Key Features:

- Sealed Design: One of the standout features of membrane switches is their sealed construction, typically using robust materials like polyester or polycarbonate. This creates a barrier against dust, liquids, and contaminants, making them highly resistant to environmental elements.

- Chemical Resistance: In environments where harsh chemicals are prevalent, membrane switches offer exceptional resistance to corrosion. They can be designed with overlays that protect the internal circuitry from chemical damage, ensuring reliable performance even in the most demanding industrial settings.

- Temperature Tolerance: Membrane switches are engineered to operate within a wide temperature range, making them ideal for extreme industrial environments. Whether it’s a freezing cold warehouse or a heat-intensive manufacturing plant, these switches maintain functionality.

Value for Clients:

In industrial settings, equipment failure can result in costly downtime. Durable membrane switches minimize the risk of failure, providing long-lasting reliability that keeps production lines running smoothly. Their ability to withstand harsh environments ensures that machines and devices continue to function at peak performance, even in the most challenging conditions.

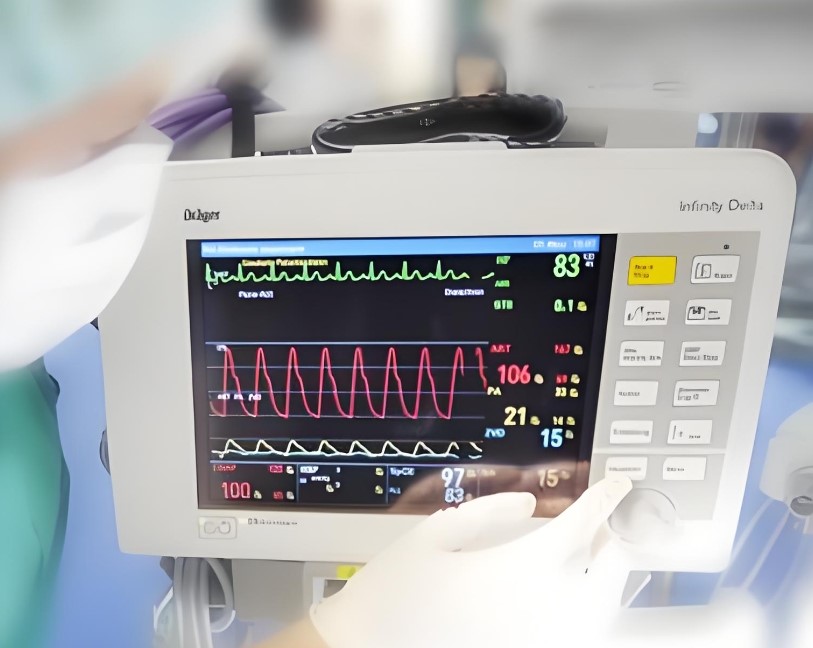

2. Seamless Integration with Medical Devices: Precision and Hygiene

The medical field demands precision and hygiene, especially when it comes to the operation of life-saving devices. Membrane switches are frequently used in medical equipment, where their easy-to-clean surfaces and precise control interfaces are essential for maintaining sterility and ensuring accurate device operation.

Key Features:

- Hygienic Design: Medical environments require surfaces that can be easily sanitized. Membrane switches feature smooth, non-porous overlays that can be regularly cleaned with disinfectants without damaging the switch. This ensures a sterile and contamination-free interface, which is critical for medical devices.

- Tactile Feedback: Membrane switches can be customized to include tactile feedback, providing healthcare professionals with an intuitive response when pressing the controls. This tactile sensation helps users confirm inputs, reducing the risk of errors during medical procedures.

- Custom Graphics and Symbols: Medical devices often require user interfaces that are clear and easy to understand. Membrane switches can be designed with custom graphics, colors, and backlighting, ensuring that doctors and nurses can quickly identify and use the correct controls in critical moments.

Value for Clients:

For healthcare professionals, having reliable and easy-to-clean control systems is vital. Membrane switches provide the precision, durability, and hygiene needed to ensure that medical devices operate accurately and safely. Their seamless integration into the medical field enhances both the usability and longevity of essential healthcare equipment.

3. Compact and Space-Saving Design: Ideal for Portable Devices

As industries and medical applications increasingly adopt portable devices, the need for compact and lightweight control systems has grown. Membrane switches are incredibly thin, making them the perfect solution for devices where space is limited. Despite their slim profile, they offer robust functionality and performance, enabling efficient control in even the smallest devices.

Key Features:

- Ultra-Thin Profile: Membrane switches can be as thin as a fraction of a millimeter, allowing them to fit into compact devices without sacrificing functionality. This makes them ideal for portable or handheld machines, where space-saving design is critical.

- Flexible Integration: The flexible nature of membrane switches means they can be mounted on curved or irregular surfaces, providing versatile design options for devices of various shapes and sizes.

- Lightweight Construction: The lightweight materials used in membrane switches contribute to the overall portability of the device. This makes them ideal for mobile medical equipment, handheld industrial tools, and wearable devices.

Value for Clients:

In industries and healthcare settings where portability and space efficiency are key, membrane switches offer a solution that doesn’t compromise on performance. Their lightweight, compact design allows manufacturers to create smaller, more portable devices without losing out on functionality or durability.

4. Customizable User Interfaces: Tailored to Specific Needs

Every industry has unique requirements when it comes to control systems. Whether it’s the need for specific button layouts, colors, or durability standards, membrane switches offer extensive customization options. This adaptability ensures that the user interface can be designed to meet the exact needs of the device or application, providing an intuitive experience for operators.

Key Features:

- Custom Layouts: Membrane switches can be tailored to include specific button configurations that suit the device’s function. Whether it’s a few simple buttons or a complex multi-layered interface, these switches provide flexibility in design.

- Backlighting Options: For applications where visibility is essential, membrane switches can be designed with LED backlighting, ensuring that controls are easily readable in low-light environments. This feature is particularly valuable in medical settings or industrial environments where proper lighting may not always be available.

- Branding and Graphics: Membrane switches can incorporate custom graphics, logos, and branding elements, providing a professional and polished look to the equipment. This adds an extra level of customization that enhances both functionality and aesthetics.

Value for Clients:

With extensive customization options, membrane switches allow manufacturers to create tailored solutions that perfectly fit their application’s needs. Whether it’s a rugged industrial tool or a precise medical device, the ability to customize the interface ensures that operators can use the equipment efficiently and intuitively.

5. Long Lifespan and Low Maintenance: A Cost-Effective Solution

Durability is a key factor in the lifespan of control systems, and membrane switches are known for their long-lasting performance. Their sealed design protects them from wear and tear, meaning they require minimal maintenance and can operate effectively for years without failure. This makes them a cost-effective solution for both industrial and medical applications.

Key Features:

- High Cycle Life: Membrane switches are designed to withstand millions of actuations, making them ideal for high-usage environments. This extended lifespan reduces the need for frequent replacements, saving costs in the long run.

- Low Maintenance: Due to their sealed construction, membrane switches require very little maintenance. The absence of moving parts means that there’s less risk of mechanical failure, and the easy-to-clean surfaces keep them functioning at their best.

- Environmental Protection: Membrane switches are built to resist moisture, dust, and other contaminants, making them highly reliable in challenging environments where other types of switches might fail.

Value for Clients:

For industries and medical applications where downtime and maintenance costs are a concern, membrane switches offer a solution that provides reliable long-term performance. Their high durability and low maintenance requirements ensure that equipment operates smoothly for years, making them a smart investment for any business.

Conclusion

From rugged industrial settings to sterile medical environments, durable membrane switches provide the ideal control solution for applications that demand reliability, customization, and ease of use. Their sealed design, resistance to harsh environments, and long lifespan make them the perfect choice for industries and healthcare providers looking for cost-effective, high-performance solutions. Whether it’s controlling industrial machines, operating medical devices, or ensuring portable device functionality, membrane switches are the key to seamless and efficient operations in today’s demanding environments.