In today's rapidly advancing technological landscape, devices need to be intuitive, durable, and versatile. A key element that supports this functionality is the membrane switch—a user-friendly, low-profile, and highly customizable interface. Whether it's for medical equipment, industrial control panels, or consumer electronics, membrane switches are designed to meet the diverse needs of various industries. Offering flexible design options, these switches are built to deliver reliability, durability, and an enhanced user experience.

In this blog post, we'll explore how membrane switch designs provide custom solutions for any industry need, focusing on the features, benefits, and applications of this technology.

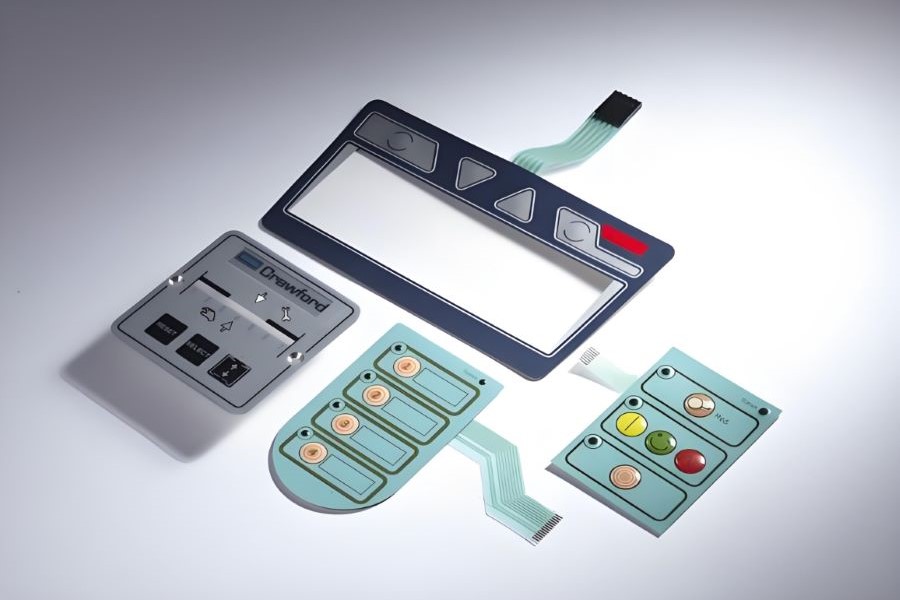

1. What Is a Membrane Switch?

A membrane switch is a type of interface used to activate and control electronic devices. It’s made of thin, flexible layers that consist of conductive elements. Unlike traditional mechanical switches, membrane switches operate through pressure-based touch, allowing users to engage the device with a gentle press on the graphic overlay.

The basic structure of a membrane switch includes:

- Graphic Overlay: The top layer that users interact with. This can be customized with symbols, colors, and branding elements.

- Circuit Layers: Below the overlay, these conductive layers allow the switch to complete a circuit when pressed.

- Adhesive Layers: These hold the layers together and ensure a secure bond with the device.

- Backer Layer: The foundation of the switch, providing structural integrity and often an adhesive for attachment to the device.

2. Tailored to Your Needs: Custom Design Options

One of the most significant advantages of membrane switches is their customizability. Every device has unique requirements, and membrane switches are designed to accommodate these differences with tailored solutions. Here’s how customization can make membrane switches the perfect fit for your product:

- Graphics and Branding: The graphic overlay can be printed with your company’s logo, symbols, and color schemes, creating a visually appealing and professional-looking interface. This not only enhances the aesthetics but also ensures brand consistency across products.

- Tactile Feedback Options: To improve the user experience, membrane switches can be designed with tactile domes that provide a noticeable click sensation when pressed. This feedback helps users confirm an action without needing to look at the control panel, making it ideal for fast-paced environments.

- Backlighting Features: If your device operates in low-light settings, LED or fiber optic backlighting can be incorporated into the membrane switch. This ensures buttons are easily visible and usable, no matter the lighting conditions.

- Waterproof and Dustproof Capabilities: Membrane switches can be sealed to provide protection against water, dust, and chemicals, ensuring they work reliably in harsh environments like industrial or medical applications.

- Embossing and Surface Finishes: Adding embossing can enhance the look and feel of buttons, creating a more interactive and professional design. Additionally, different surface finishes can offer either matte or glossy appearances to suit the product’s design requirements.

3. Durability for Tough Environments

When designing devices for industries like healthcare, manufacturing, or military, durability is a top priority. Membrane switches are built to withstand extreme environments and heavy usage without compromising performance. Here’s how they deliver on durability:

- Wear Resistance: The materials used in membrane switches are designed to endure millions of presses over their lifespan. High-quality polyester, polycarbonate, and other industrial-grade materials ensure these switches remain functional even after extensive use.

- Temperature Resistance: Membrane switches can be designed to work in extreme temperatures, both high and low, without losing functionality. This makes them ideal for outdoor equipment or devices exposed to fluctuating temperatures.

- Chemical Resistance: In industries where devices are exposed to chemicals—such as manufacturing plants or medical environments—membrane switches can be made with chemical-resistant materials that prevent degradation.

This durability ensures a long lifespan, reducing maintenance costs and downtime for your devices.

4. Seamless Integration with Device Design

Another standout feature of membrane switches is their ability to seamlessly integrate with various devices. Whether you need a flat, minimalist interface or a multi-functional control panel, membrane switches can be designed to match the form factor of your product without adding bulk.

- Compact and Lightweight: Membrane switches are slim and lightweight, which makes them an excellent option for devices where space is limited. They offer an efficient solution for integrating controls into portable or handheld devices without compromising functionality.

- Flexible Configurations: The layers of membrane switches can be easily adapted to the size, shape, and specific layout required by your device. Whether you need a large, simple interface or a more complex arrangement with multiple functions, membrane switches offer unparalleled flexibility.

5. Cost-Effective Manufacturing and Maintenance

Membrane switches are not only highly functional but also cost-effective to produce. The relatively simple construction of these switches, compared to mechanical alternatives, means they can be manufactured at a lower cost while still offering high reliability and durability.

Additionally, the low-maintenance design of membrane switches reduces the likelihood of mechanical failure. With fewer moving parts and a sealed structure, these switches are less prone to wear and tear, saving companies on replacement and repair costs over time.

6. Industry Applications: Meeting Diverse Needs

Membrane switches are used in a wide array of industries, thanks to their customizable nature and reliable performance. Here’s a look at some of the industries where membrane switches have become indispensable:

- Medical Equipment: Membrane switches are commonly used in medical devices, where cleanliness, precision, and durability are critical. Their easy-to-clean surfaces and sealed designs make them perfect for healthcare settings.

- Industrial Machinery: In manufacturing environments, membrane switches provide reliable, long-lasting control interfaces for heavy machinery and automated systems. Their resistance to moisture, dust, and harsh chemicals ensures that they perform reliably even in challenging conditions.

- Consumer Electronics: Many household appliances, remote controls, and fitness equipment rely on membrane switches for their sleek design and ease of use. Their compact form and customizable designs make them ideal for consumer products.

- Automotive: Membrane switches are found in the automotive industry for dashboard controls and infotainment systems. Their rugged construction ensures they hold up well to constant use in varying temperature conditions.

These examples highlight the versatility of membrane switches and how they are easily adapted to the specific needs of any industry.

7. Sustainability and Eco-Friendly Options

For companies looking to minimize their environmental impact, membrane switches offer sustainable manufacturing options. The materials used can be sourced from environmentally responsible providers, and the manufacturing process itself generates minimal waste. Companies committed to reducing their carbon footprint can benefit from the eco-friendly potential of membrane switches.

8. Simplified User Experience

Membrane switches offer a streamlined, intuitive user experience, which is especially important in complex devices that require quick and accurate inputs. The graphic overlay can be designed to feature easy-to-read labels, color coding, and icons, ensuring that users can operate the device with minimal training.

Whether it’s a nurse using medical equipment or an operator in an industrial setting, membrane switches make interactions with devices simple and efficient, enhancing overall productivity.

Conclusion: The Ultimate Solution for Any Industry

Custom membrane switches are a versatile, reliable, and efficient solution for any industry that requires user-friendly and durable control interfaces. With a wide range of customization options, including tactile feedback, backlighting, and waterproofing, membrane switches can be tailored to meet the specific demands of your devices.

Their durability, flexibility, and cost-effectiveness make them the ideal choice for industries ranging from medical to industrial to consumer electronics. Whether you need to streamline operations, enhance user experience, or increase the longevity of your devices, membrane switches offer a custom solution that fits perfectly with your industry’s unique needs.

Unlock the potential of your devices with custom membrane switches and experience the benefits of a more efficient, reliable, and cost-effective user interface solution.