Membrane switches are essential components in a variety of electronic devices, from industrial machinery to household appliances. These switches play a crucial role in user interfaces, providing a cost-effective and durable solution for controlling devices. However, like any piece of technology, membrane switches are susceptible to wear and tear. When they malfunction or fail, the question arises: can membrane switches be repaired, or do they need to be replaced?

In this article, we will explore the factors that determine whether a membrane switch can be repaired or must be replaced. We will delve into the repair process, common issues that require troubleshooting, and provide insights into when replacement is the most viable solution. With a clear understanding of these factors, you can make an informed decision about maintaining your membrane switches, ultimately saving time and costs.

What Are Membrane Switches?

What Are Membrane Switches?

Before we explore repair versus replacement, it’s important to understand what membrane switches are and how they function.

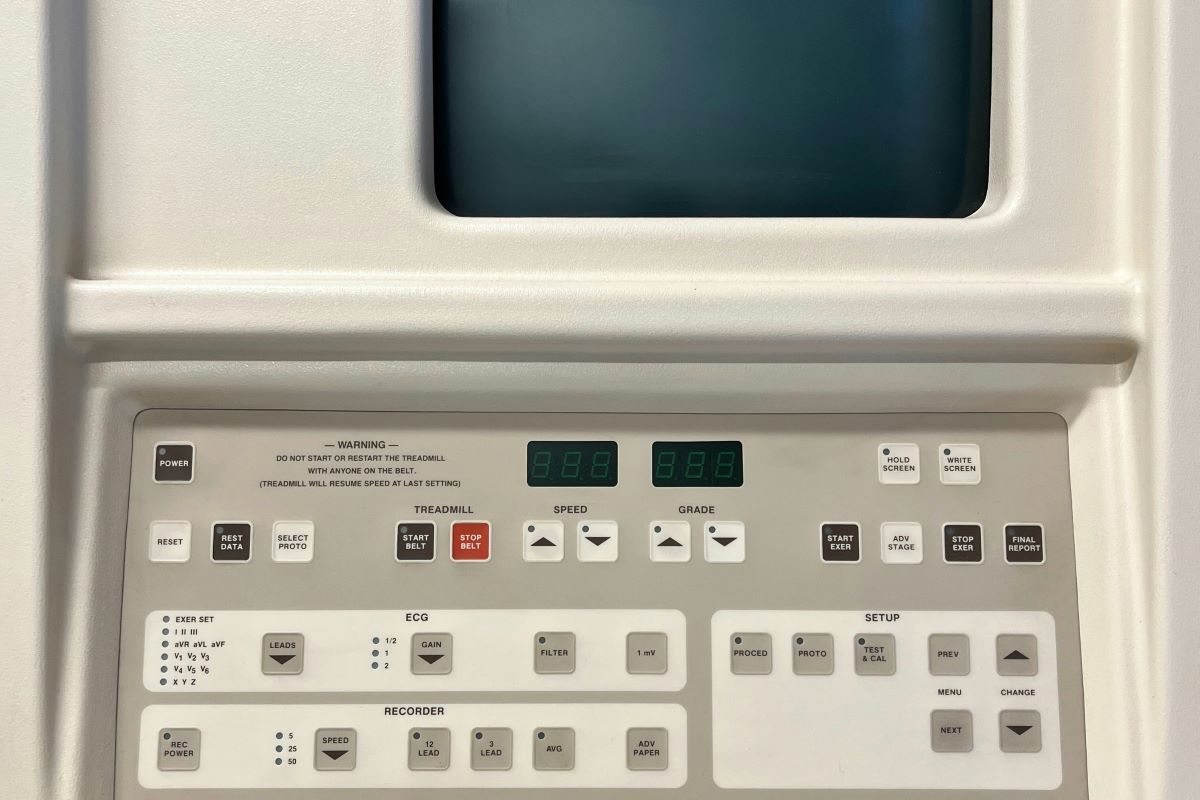

A membrane switch is a type of electrical switch commonly used in various electronic devices. It consists of several layers, including a flexible substrate, conductive traces, and a top layer with printed graphics. The primary function of a membrane switch is to provide a user interface for a device, allowing users to input commands via physical pressure on the surface.

The layers of the switch include:

Top Layer (Graphic Overlay): This is the visible surface with printed symbols or text that guide users.

Circuit Layers: These conductive layers connect to the device's internal circuitry, enabling electrical signals to pass through when the switch is activated.

Spacer Layers: These layers separate the circuit layers, ensuring that they don’t come into contact with each other until pressure is applied.

Membrane switches are popular because of their low cost, lightweight design, and versatility. However, their durability can be affected by factors such as frequent use, environmental conditions, and physical wear.

Common Issues with Membrane Switches

Like any component, membrane switches can develop issues over time. Understanding these problems can help in troubleshooting and determining whether repair or replacement is necessary.

1. Unresponsive Buttons

One of the most common issues with membrane switches is when certain buttons or regions of the switch become unresponsive. This can occur due to:

Worn-out conductive traces that can no longer properly transmit electrical signals.

Damaged or degraded contact pads that fail to establish a connection when pressed.

2. Physical Damage

Physical damage can occur from excessive force, exposure to moisture, or harsh environmental conditions. Common forms of physical damage include:

Tears in the overlay layer

Cracking of the membrane

Water ingress, leading to internal corrosion

3. Poor Sensitivity or Inconsistent Feedback

Sometimes, membrane switches experience inconsistent sensitivity where some presses register, while others do not. This could be due to:

Dirt or debris trapped between layers affects the electrical contact.

Wear on the conductive layers from constant use.

4. Visual Damage or Fading

Over time, the graphic overlay may fade, becoming difficult to read. This is more common in devices that are exposed to UV light or extreme temperatures. Fading graphics can make it difficult for users to navigate the controls, even if the switch is functioning properly.

Can Membrane Switches Be Repaired?

The answer to whether a membrane switch can be repaired depends on the extent of the damage and the specific issue at hand. In many cases, minor issues can be addressed through repairs, while more severe damage may require a complete replacement. Below are some common repair options for membrane switches:

1. Cleaning and Maintenance

For issues like unresponsiveness or inconsistent feedback, cleaning the switch is often the first step in the repair process. Dirt, dust, and debris can accumulate between the layers of the membrane, causing electrical interference. Cleaning the switch gently with a soft cloth and non-abrasive cleaner may resolve the issue.

In some cases, compressed air or a mild solvent may be used to clear any debris from the switch’s contact pads.

2. Rebuilding Conductive Traces

If the conductive traces are damaged but not destroyed, it may be possible to repair them using conductive ink or a repair kit. Conductive ink can be applied to the affected area to restore the electrical connection. However, this method is only effective if the damage is not extensive.

3. Replacing Components

In some cases, individual components of the membrane switch, such as the graphic overlay or spacer layers, can be replaced without replacing the entire unit. This is an option if the damage is confined to these non-electrical components.

For instance, if the graphic overlay is faded or torn, you can replace just the overlay while keeping the rest of the switch intact. This approach may save costs and time compared to replacing the entire switch.

4. Addressing Water Damage

If the membrane switch has suffered from water ingress, it may be possible to dry out the device and address any corrosion issues using a specialized cleaning solution. In severe cases of corrosion or if the internal layers are damaged, the switch may need to be replaced.

When Should a Membrane Switch Be Replaced?

While repair is often an option for minor issues, there are cases where replacement is the best solution. If any of the following conditions apply, replacement may be necessary:

1. Severe Physical Damage

If the membrane switch has significant tearing, cracking, or other forms of physical damage that cannot be repaired effectively, it’s often more cost-effective to replace the entire switch.

2. Extensive Electrical Failure

If multiple buttons or the entire switch are unresponsive due to damaged conductive traces or failed electrical circuits, the cost of repair may outweigh the cost of replacement.

3. Continuous or Frequent Failures

If the membrane switch continues to fail despite repeated repairs, it may be time to replace it. Repeated repairs can become costly and may not restore the switch to its optimal functionality.

4. Outdated Technology

In some cases, older membrane switches may not meet the current standards for functionality or aesthetics. If the design or technology has become outdated, replacing the switch with a newer model may be the best option.

Troubleshooting Membrane Switches

Before deciding to repair or replace a membrane switch, performing basic troubleshooting can help you identify the underlying issue. Here are some common troubleshooting steps:

Check for Dirt or Debris: Clean the switch to remove any foreign materials that may be causing contact issues.

Inspect for Visible Damage: Look for signs of physical damage, such as cracks or tears in the overlay layer.

Test the Electrical Circuit: Use a multimeter to check the conductivity of the switch’s internal traces. This can help identify any electrical failures.

Assess the Environment: Consider whether exposure to moisture, temperature extremes, or UV light may have affected the switch.

Conclusion

In summary, whether a membrane switch can be repaired or needs to be replaced depends on the nature and extent of the damage. Minor issues such as dirt buildup or fading overlays can often be repaired, while severe physical damage or electrical failures may require a full replacement. It is crucial to assess the switch carefully, troubleshoot any issues, and determine whether the repair cost justifies the replacement.

For businesses relying on membrane switches for critical applications, maintaining these components properly and knowing when to repair or replace them can extend their lifespan and ensure smooth operations. If in doubt, consulting with an expert or a membrane switch supplier can provide valuable guidance on the best course of action.