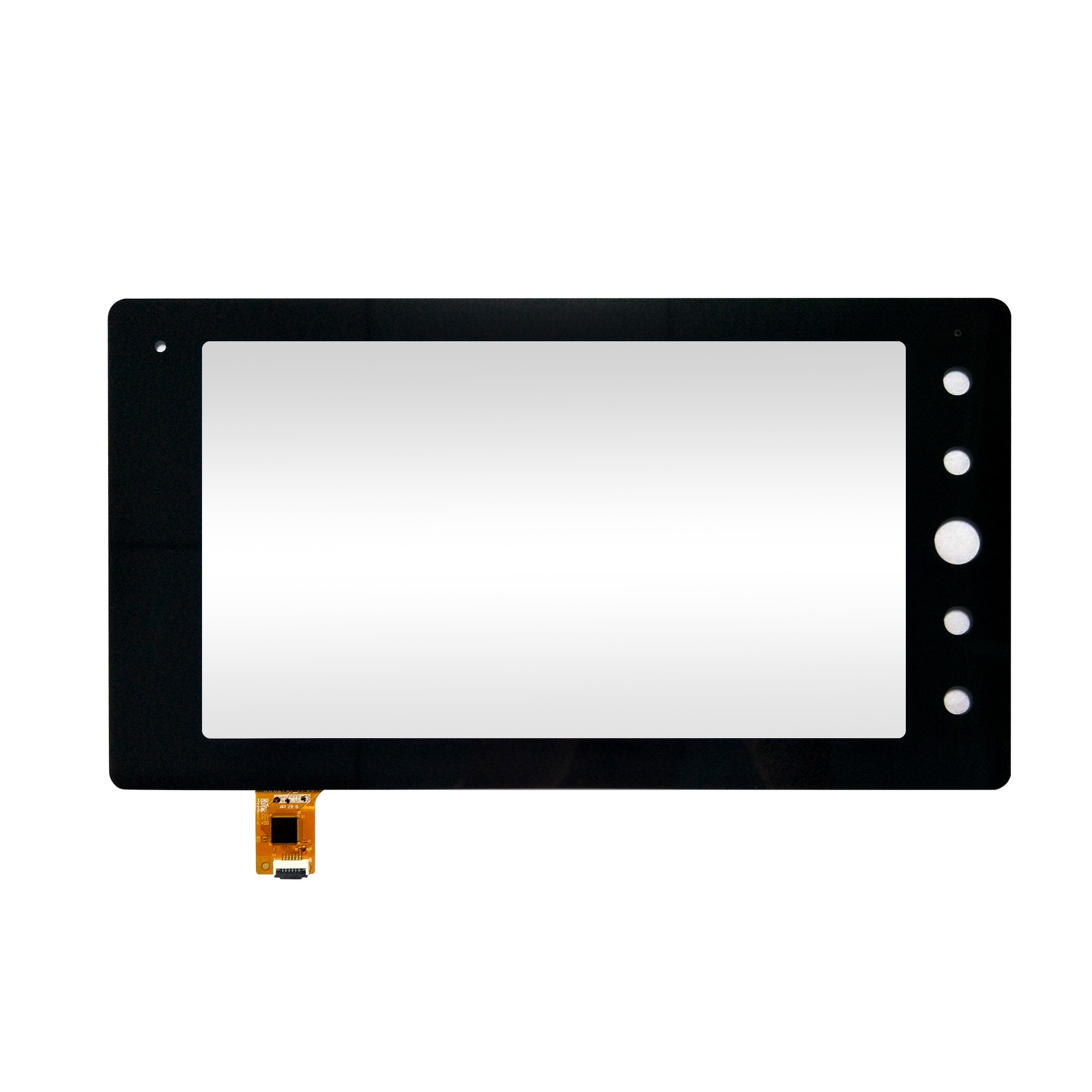

The role of custom capacitive touch panels has become central in human–machine interaction. As industries demand higher precision, durability, and design flexibility, material science continues to shape the performance of modern touch solutions. From smartphones to industrial equipment, the selection of substrates such as glass, PET films, and flexible materials defines not only usability but also long-term reliability.

This article explores the scientific foundation of materials used in capacitive touch technology. Examining the strengths and trade-offs of glass substrates, polymer films, and flexible layers reveals how each contributes to the advancement of interactive design.

Glass Substrates: Strength and Transparency

Glass remains a primary material in capacitive touch panels because of its excellent optical clarity, hardness, and chemical resistance. Its transparency allows for superior display visibility, while its rigidity supports precise electrode alignment.

Tempered or chemically strengthened glass ensures scratch resistance and durability under frequent contact. Furthermore, thin glass substrates balance structural strength with reduced weight, enabling slim designs in consumer devices.

Electrical performance also benefits from glass stability. Uniform surface properties allow consistent capacitive sensing, minimizing signal interference. Coatings, such as anti-glare and anti-smudge layers, enhance user experience and maintain long-term clarity.

However, glass has inherent limitations. Its rigidity reduces flexibility, making it less suitable for devices requiring curved or bendable surfaces. Despite this, glass remains indispensable in applications demanding strength and high-quality optics.

Polyethylene Terephthalate (PET) Films: Lightweight and Versatile

PET film touch panels have gained prominence due to their lightweight nature, cost-effectiveness, and processing flexibility. PET offers high transparency while being much thinner and lighter than glass, making it ideal for portable devices and applications where weight reduction is crucial.

Manufacturers can easily pattern conductive layers on PET, enabling custom designs for different industries. The flexibility of PET allows touch panels to conform to slight curves, expanding design possibilities beyond flat surfaces.

In addition, PET films demonstrate good chemical resistance and moderate mechanical strength. When combined with hard coatings, PET panels resist scratches and extend usability.

Nevertheless, PET lacks the hardness of glass. Prolonged use may lead to surface wear, and sensitivity can be affected by environmental factors such as humidity. Even so, PET remains attractive where cost, weight, and design adaptability are priorities.

Flexible Substrates: Shaping the Future of Interaction

The emergence of flexible substrate touch panels marks a shift toward next-generation applications. Materials such as polyimide and advanced composites enable panels that bend, fold, or stretch without compromising capacitive sensing.

Flexible substrates allow integration into wearables, foldable devices, and automotive interiors. Their ability to conform to irregular surfaces opens opportunities in medical equipment and industrial interfaces, where adaptability is essential.

Material innovation ensures durability under repeated bending cycles. Engineers design these substrates with layered structures that maintain electrical integrity, even under mechanical stress.

While flexible materials enhance design freedom, they require precise engineering. Signal consistency, electrode adhesion, and long-term stability are ongoing challenges. Advances in nanomaterials and conductive inks are addressing these limitations, pushing the boundaries of flexible touch technology.

Comparative Analysis of Materials

Each substrate contributes unique advantages to custom capacitive touch panels:

Glass offers unmatched strength, optical quality, and stability.

PET films deliver lightweight versatility at lower costs.

Flexible substrates enable novel designs for emerging applications.

Material selection depends on end-use requirements. For example, smartphones prioritize durability and clarity, favoring glass. Industrial control panels often balance cost and function, making PET an ideal choice. Wearables and foldable electronics demand flexibility, highlighting the importance of flexible substrates.

The interplay between cost, performance, and innovation guides engineers toward optimal material combinations. Hybrid solutions that integrate glass and films or layered composites demonstrate how manufacturers tailor performance for specific industries.

Engineering Considerations in Material Application

Beyond material choice, engineering practices determine the effectiveness of touch panels. Layer bonding, electrode deposition, and surface treatments all influence sensitivity and durability.

Bonding adhesives must align with substrate properties to avoid delamination. Transparent conductive coatings, often indium tin oxide (ITO), require uniform deposition to ensure accuracy. Surface textures influence both tactile feel and optical reflection, affecting user satisfaction.

Moreover, designers must consider environmental resilience. Panels used in industrial or outdoor environments must withstand temperature fluctuations, UV exposure, and contaminants. Proper encapsulation and protective films extend panel lifespans in demanding conditions.

Applications Across Industries

The adaptability of custom capacitive touch panels drives their adoption in diverse sectors:

Consumer electronics: Smartphones, tablets, and wearables.

Automotive: Infotainment systems, dashboards, and control surfaces.

Industrial equipment: Human–machine interfaces requiring durability and precision.

Medical devices: Touch-enabled controls with high hygienic standards.

In each case, material selection determines not only function but also product lifespan and user satisfaction. This highlights the importance of understanding the science behind substrates when designing touch solutions.

Future Directions in Material Innovation

Material science continues to expand the capabilities of capacitive touch technology. Research focuses on conductive polymers, graphene, and nanocomposites to enhance flexibility and transparency. These innovations aim to reduce reliance on brittle or costly materials while maintaining performance.

Advances in coating technologies further improve resistance to scratches, fingerprints, and contaminants. Additionally, sustainable substrates are gaining attention, aligning touch panel manufacturing with global environmental goals.

The convergence of new materials, advanced deposition methods, and smart design principles ensures that custom capacitive touch panels will remain integral to the future of digital interaction.

Conclusion: Materials as the Foundation of Innovation

The science behind custom capacitive touch panels demonstrates that material choice is fundamental to performance, reliability, and design freedom. Glass provides clarity and strength, PET films offer lightweight adaptability, and flexible substrates open possibilities for future devices.

Each substrate addresses distinct challenges, and together they shape a versatile toolkit for engineers across industries. As innovation progresses, the synergy between materials and technology will define the next era of interactive systems.

For companies committed to advanced user interfaces, investing in material science is not optional—it is essential for creating durable, precise, and future-ready capacitive touch solutions.