Membrane switch assemblies are integral to modern industrial devices, providing a seamless interface for complex machines. Known for their compact design, durability, and customizable features, membrane switches enhance user interaction, boost efficiency, and reduce the complexity of machine operation. In this guide, we’ll explore how membrane switch assemblies improve user experience in industrial applications, focusing on their key features, solutions for common challenges, application versatility, and benefits to both operators and manufacturers.

Key Selling Points of Membrane Switch Assemblies

Enhanced Durability for Harsh EnvironmentsMembrane switches are built with durable, high-quality materials that resist wear and tear, even in challenging conditions. This durability makes them ideal for industrial applications where equipment may be exposed to dust, moisture, and varying temperatures.

Customization for Specific User NeedsIndustrial applications often require specialized designs to accommodate unique functions. Membrane switch assemblies offer extensive customization options, such as backlighting, tactile feedback, and custom graphic overlays, allowing companies to tailor the interface to specific user requirements.

Cost-Effective Production and MaintenanceCompared to mechanical switches, membrane switches are more cost-effective to produce and maintain. They have fewer moving parts, which reduces the likelihood of failure and lowers maintenance costs over time. This benefit is especially significant in industries that rely on large numbers of machines.

Sealed and Waterproof DesignThe sealed structure of membrane switches offers robust protection against moisture, chemicals, and dust. This feature is essential for industries where equipment may be exposed to liquids, making these switches ideal for food processing, medical devices, and chemical production.

Enhanced User Feedback and SafetyMembrane switches can include tactile feedback, audible clicks, or backlit keys that help users operate machinery with confidence and precision. This feedback is crucial for maintaining safety in fast-paced industrial settings.

Addressing User Pain Points with Membrane Switch Assemblies

Reducing Operator Fatigue with Ergonomic DesignIn industrial settings, operators often work long hours. The ergonomic design of membrane switches, combined with customizable tactile feedback, reduces strain and fatigue on users' fingers, helping to maintain productivity and minimize discomfort.

Increasing Efficiency with Simplified InterfacesIndustrial equipment can be complex, with numerous buttons and controls. Membrane switch assemblies streamline the user interface by organizing essential controls intuitively, minimizing the risk of errors, and allowing for faster, more efficient operation.

Minimizing Downtime Due to Switch FailureFrequent equipment malfunctions can significantly impact productivity. Membrane switches’ durable, long-lasting design reduces the need for repairs and replacements, leading to less downtime and lower operating costs.

Providing Reliable Operation in Extreme ConditionsMembrane switches withstand harsh environmental conditions better than most other types of switches. Their waterproof, dustproof, and chemical-resistant design ensures reliable performance in extreme industrial environments, providing peace of mind to operators.

Applications of Membrane Switch Assemblies in Industrial Settings

Manufacturing and Production EquipmentMembrane switches are widely used in manufacturing for operating machinery, controlling production lines, and managing automated processes. Their rugged design and resistance to contaminants make them ideal for handling daily wear in production environments.

Medical and Laboratory EquipmentIn medical and lab environments, devices must meet stringent hygiene and performance standards. Membrane switches’ sealed and waterproof design makes them easy to clean and sterilize, making them a trusted choice for medical equipment panels.

Aerospace and Defense SystemsPrecision and reliability are crucial in aerospace and defense applications. Membrane switch assemblies provide responsive, reliable interfaces that function well in high-altitude and high-stress conditions, enhancing user control in critical operations.

Agricultural and Outdoor EquipmentFor outdoor machinery used in agriculture or construction, membrane switches offer a durable, weather-resistant interface that withstands exposure to the elements. Their rugged design enables operators to control machinery without concern for environmental damage.

Food and Beverage ProcessingIn food processing plants, equipment must meet high cleanliness standards. Membrane switches' smooth, sealed surfaces are easy to sanitize and prevent debris from accumulating, making them ideal for use in food processing applications.

Advantages of Using Membrane Switch Assemblies

High Reliability with Fewer Mechanical PartsUnlike traditional switches with many mechanical components, membrane switches have fewer parts that can wear out or malfunction. This simplicity leads to enhanced reliability, providing a longer lifespan and reducing maintenance requirements.

Streamlined Design with Minimal BulkMembrane switches are thin and lightweight, helping equipment maintain a sleek, minimalistic design. This compact structure is valuable in applications where space is limited or a streamlined interface is desirable.

Improved Safety with Anti-Contamination FeaturesMany industrial settings deal with dust, oil, or chemicals that can damage standard switches. The sealed design of membrane switches prevents contaminants from entering the interface, ensuring safe and stable operation over time.

Supports Backlighting for Low-Light EnvironmentsMembrane switches can integrate backlighting, making them usable in low-light conditions such as warehouses or nighttime operations. This feature enhances visibility and reduces the likelihood of errors, contributing to operator safety.

Reduced Operator Training TimeA simplified, intuitive interface allows new operators to learn equipment controls quickly. The customizable icons, labels, and color-coded buttons make the membrane switch user-friendly, minimizing the time and resources spent on training.

Design Features of High-Quality Membrane Switch Assemblies

Custom Graphic Overlays for User ClarityMembrane switch assemblies can feature graphic overlays that clearly label each button’s function. These overlays are often customizable, allowing manufacturers to include symbols, colors, or icons that match industry standards, making operation intuitive.

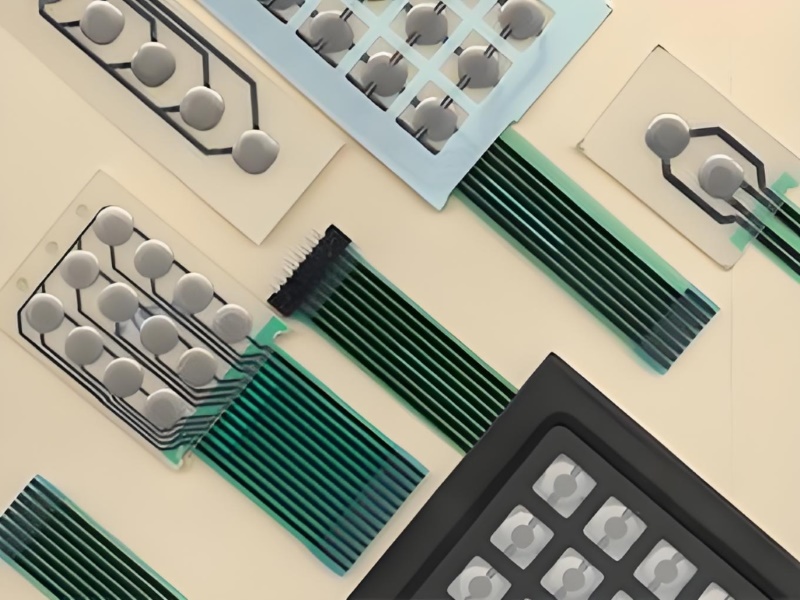

Tactile and Non-Tactile Feedback OptionsMembrane switches can be designed with tactile domes that provide a physical "click" sensation when pressed, ensuring users know when a button has been activated. For applications where tactile feedback is unnecessary, non-tactile options provide a smooth, flat surface.

Polyester and Polycarbonate Materials for DurabilityMost membrane switches are constructed from durable materials like polyester or polycarbonate, which are resistant to impact and chemicals. These materials ensure the switch assembly can handle the demands of industrial use without degrading.

Flex Circuit Technology for Enhanced PerformanceMany membrane switches incorporate flexible circuits, which allow the assembly to bend and conform to curved surfaces. This flexibility enables custom-fit designs and reduces the likelihood of circuit damage from bending or impact.

Integration of Advanced TechnologiesAdvanced membrane switches can incorporate touch-sensitive areas, resistive touch sensors, or even capacitive touch technology, allowing for greater versatility and integration with other modern industrial technologies.

Value of Investing in Membrane Switch Assemblies

Lower Total Cost of OwnershipMembrane switches are a cost-effective solution for industries looking to reduce long-term expenses. Their durable design minimizes the need for repairs and replacements, lowering the total cost of ownership over time.

Enhanced Operational Efficiency and ProductivityWith an intuitive, reliable interface, operators can work more efficiently and effectively. Membrane switches allow for smooth, responsive control of equipment, helping to optimize workflows and enhance productivity.

Flexibility in Customization for Brand DifferentiationCompanies can tailor membrane switch designs to align with brand aesthetics and functional requirements. Custom graphics, colors, and overlays enable businesses to distinguish their equipment from competitors, adding value to their offerings.

Eco-Friendly Materials and Long LifespanMembrane switches use eco-friendly materials that are RoHS and REACH compliant, aligning with environmental regulations. Additionally, their long lifespan reduces waste, making them a sustainable choice for companies focused on green practices.

Adaptable to Evolving Industry StandardsAs industries adopt new technologies, membrane switches can be modified to incorporate the latest advancements, such as capacitive touch or IoT connectivity. This adaptability ensures that companies can keep their equipment current and competitive.

Conclusion

Membrane switch assemblies have become a staple in industrial applications, offering a reliable, durable, and customizable interface for complex machinery. From withstanding harsh environmental conditions to supporting efficient machine operation, these switches significantly enhance user experience. Their design flexibility, ease of use, and resilience make them ideal for a wide range of industries, including manufacturing, healthcare, and aerospace. By investing in membrane switch assemblies, companies can improve operational efficiency, ensure user safety, and reduce long-term costs. As industrial environments continue to evolve, membrane switches stand out as a forward-thinking solution that meets the demands of today’s technology-driven landscape.