Customizing membrane switches offers several advantages and disadvantages. Here’s a detailed analysis of these factors:

Advantages:

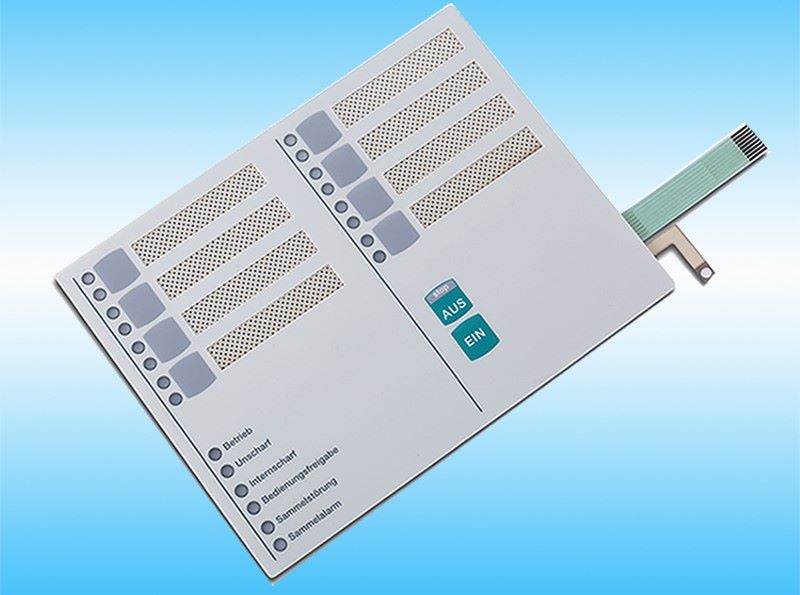

Personalized Customization: Membrane switches can be tailored to meet specific customer needs, including customizations in appearance, color, size, and tactile feedback. This flexibility allows for adaptation to diverse market requirements and enhances user satisfaction.

High Quality and Durability: Customized membrane switches are typically manufactured using high-quality materials and advanced production techniques, ensuring exceptional tactile response, durability, and stability. They are designed to endure long-term use and frequent pressing without degradation, offering superior wear resistance.

Sealing and Protection: These switches offer excellent sealing properties, effectively guarding against moisture, dust, and other harmful substances. This protection ensures that internal circuits and components remain intact, making them ideal for use in humid, dusty, or corrosive environments.

Thin and Aesthetic: Membrane switches are both thin and lightweight, which optimizes space and contributes to a sleek, attractive design. Customizable aesthetics further enhance the visual appeal and perceived quality of the final product.

Economic and Efficient: While initial investments in customized membrane switches may be higher, they prove cost-effective in the long run. They cater precisely to customer needs, boosting satisfaction and market competitiveness. Additionally, their longevity and low maintenance requirements help reduce overall operating costs, offering significant economic benefits.

Disadvantages:

Higher Cost: Customized membrane switches generally involve higher costs compared to standard options. This is due to additional expenses such as design fees, mold fees, and production adjustment costs. As a result, customized switches tend to be more expensive than their standardized counterparts.

Long Production Cycle: The design and production of customized membrane switches require more time, leading to a longer production cycle. This extended timeline can impact delivery schedules and responsiveness to market demands.

High Technical Requirements: Designing and producing customized membrane switches demands a high level of technical expertise. Inadequate technical capability or experience on the part of the manufacturer can lead to inconsistent product quality or failure to meet specific customer requirements.

Limited Flexibility: While customized membrane switches offer significant flexibility, there are still constraints. Certain complex designs or functionalities might be challenging to achieve due to limitations in production equipment and processes, potentially requiring additional investment.

In summary, membrane switch customization offers several advantages, including personalized design options, high quality and durability, effective sealing and protection, a slim and aesthetically pleasing profile, and cost-efficiency over time. However, it also presents some challenges, such as higher costs, longer production cycles, demanding technical requirements, and certain limitations in flexibility. When considering membrane switch customization, it's crucial to weigh these benefits and drawbacks against your specific needs and budget to make an informed decision.