In industrial environments, precision and reliability define user experience. Among control devices, silicon keypads play a crucial role. Their tactile response affects operator efficiency, safety, and confidence. While many may overlook keypad feel, industrial professionals recognize its critical influence. Engineers and designers increasingly focus on tactile response as a functional parameter, not just a comfort feature.

Silicon keypads offer durability, chemical resistance, and a flexible design. Yet the tactile element differentiates average control interfaces from superior ones. The science behind tactile feedback explains why feel matters. Every keystroke transmits mechanical and sensory information to the user. In high-stakes environments such as manufacturing, medical devices, and automotive controls, consistent and predictable feedback is essential.

Understanding Tactile Response in Silicon Keypads

Tactile response refers to the mechanical and sensory cues a user experiences when pressing a key. These cues include travel distance, actuation force, rebound, and audible click. Each factor contributes to perceived quality and usability.

Travel distance influences comfort and accuracy. Keypads with optimized travel provide sufficient motion without causing fatigue. Actuation force determines the energy required to register input. Too light a force may cause accidental activation, while excessive force can slow operation. Rebound and return speed affect repeated use, critical for high-frequency industrial controls. Audible cues further reinforce confirmation of successful actuation.

For industrial operators, predictable tactile feedback reduces errors. In emergency scenarios, rapid recognition of key activation can prevent accidents or equipment damage. Engineers design silicon keypads to balance force, travel, and feedback for optimal response.

Material Science Behind Silicone Keypads

Silicone elastomers form the basis of high-performance keypads. Their flexibility, chemical resistance, and thermal stability make them ideal for industrial environments. Yet material selection directly impacts tactile response.

Shore hardness, a measure of material rigidity, dictates force and rebound. Softer silicone produces gentler actuation but may reduce precision. Harder formulations enhance feedback but can increase operator fatigue. Advanced silicon keypads combine multiple durometers to create zones with distinct tactile properties. This engineering ensures both comfort and accuracy.

Silicone’s viscoelastic properties allow controlled energy transfer. Proper formulation reduces vibration transmission, enhancing a consistent feel across temperature variations. Additives may improve wear resistance, UV stability, or chemical compatibility, preserving tactile performance over long-term use.

Design Considerations for Industrial Applications

Keypad geometry and dome design influence tactile response. In membrane switch applications, domes or pillars beneath keys create the mechanical snap. Dome thickness, height, and material interact to define force-travel characteristics.

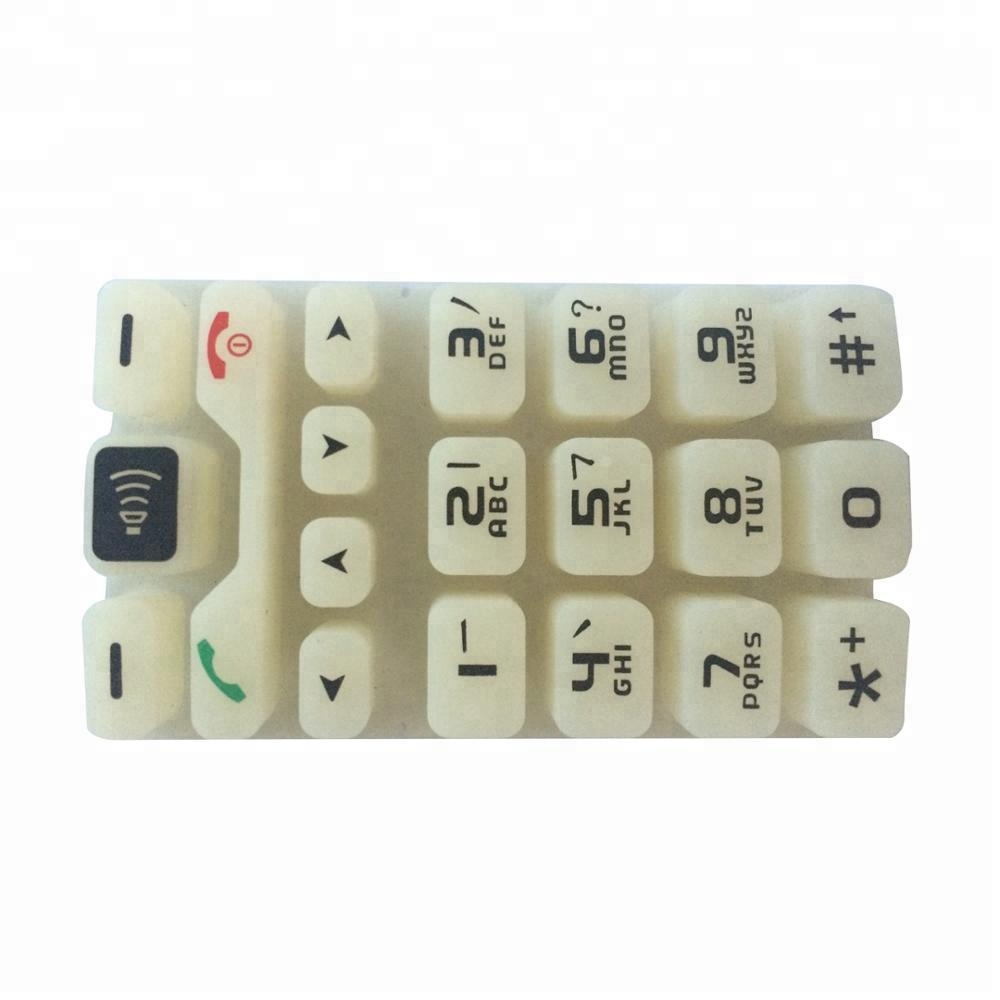

Customizing dome profiles allows designers to achieve specific feedback. Low-profile domes reduce overall keypad height while maintaining actuation clarity. High-profile domes provide a pronounced “click,” enhancing user confidence. Silicon keypads also support embossed surfaces and textures, further improving tactile perception.

In critical industrial systems, key spacing and layout are equally important. Uniform spacing prevents mispresses, while ergonomic arrangements reduce hand strain. Transitioning from standard to optimized layouts requires careful evaluation of tactile dynamics to ensure each key performs predictably under repeated use.

Manufacturing Precision and Quality Control

CNC tooling and molding processes govern silicon keypad quality. Dimensional accuracy ensures each key actuates consistently. Variations in dome height, wall thickness, or material distribution can compromise tactile uniformity.

Quality control procedures include force testing, actuation cycle counts, and tactile consistency measurements. Advanced sensors measure displacement, force, and rebound, providing objective data to validate design. Maintaining uniformity across production batches ensures operators receive the same feel across devices.

Surface finish also impacts tactile perception. Smooth finishes reduce friction, while textured or coated surfaces enhance grip. Chemical treatments may prevent contamination, maintaining tactile integrity in harsh industrial environments.

Ergonomic and Human Factors Considerations

Operator efficiency depends on both tactile and cognitive feedback. Silicon keypads transmit information through multiple channels: mechanical, auditory, and proprioceptive. Designers optimize these factors to reduce cognitive load.

Ergonomic studies demonstrate that well-calibrated actuation force and travel distance reduce fatigue. Users can operate machines for extended periods without loss of accuracy. Audible and tactile cues provide confirmation, allowing operators to focus on processes rather than double-checking inputs.

Furthermore, tactile differentiation can indicate function. For example, emergency stop keys often require a distinct actuation force or dome profile. Specialized tactile coding reduces errors and improves safety compliance in industrial settings.

Environmental and Operational Factors

Industrial keypads must perform under variable conditions. Temperature extremes, moisture, chemicals, and dust can influence tactile response. Silicone’s chemical stability ensures a consistent feel under harsh exposure.

Temperature can soften or harden silicone, altering the actuation force. Engineers compensate by selecting material grades with stable mechanical properties. Sealed or coated designs protect against liquid ingress while preserving tactile integrity.

Repetitive stress from high-frequency operations also impacts long-term performance. Properly engineered silicon keypads maintain consistent response over hundreds of thousands of cycles. Durability and reliability are essential for critical control systems.

Integration with Electronic Systems

Tactile performance does not exist in isolation. It integrates with membrane switches, circuit overlays, and backlighting systems. Silicon keypads must transmit reliable input to the underlying electronics while preserving tactile quality.

Keypad thickness, dome compression, and spacer layers influence both feel and electrical actuation. Designers balance tactile cues with electrical thresholds to ensure consistent activation. Innovations such as multi-layer designs or capacitive overlays maintain precise tactile feedback while supporting advanced functionality.

Customizing Tactile Profiles for Specific Applications

Industrial controls vary widely in user requirements. Some applications prioritize rapid actuation; others emphasize deliberate confirmation. Silicon keypads can be tailored with customized dome profiles, hybrid durometer zones, and varying travel distances.

For example, medical devices require quiet, low-force actuation to reduce noise and prevent user fatigue. Manufacturing equipment may use firmer, clicky feedback to reassure operators under high-vibration conditions. The versatility of silicon allows engineers to fine-tune tactile response for any environment.

Custom legends, textures, and embossed features further enhance usability. Keypads can combine functional markings with tactile cues, helping users identify critical controls by feel alone. This integration improves efficiency and reduces operational errors.

Testing and Validation of Tactile Response

Ensuring tactile consistency requires rigorous testing. Force-displacement curves quantify dome performance. Repeated actuation cycles simulate long-term usage. Environmental stress tests verify consistent response under temperature and humidity extremes.

High-fidelity testing ensures that silicon keypads retain both mechanical and sensory qualities throughout their service life. Objective data confirms that tactile feedback meets user expectations and operational requirements.

Impact on Industrial Safety and Productivity

Predictable tactile response contributes directly to safety. Operators can rely on precise key activation without visual confirmation, reducing reaction time during emergencies.

Productivity also benefits. Efficient tactile feedback enables faster input, fewer errors, and reduced operator fatigue. In high-volume industrial environments, these advantages scale significantly, impacting both output quality and operational efficiency.

Emerging Trends in Silicon Keypad Design

Technological advancements continue to enhance tactile capabilities. Trends include:

Multi-durometer keypads for differentiated feedback

Hybrid silicone and membrane overlays for improved durability

Embedded sensors for touch-sensitive or haptic feedback

Integrated lighting for visual and tactile confirmation

These innovations rely on precise material engineering, design, and manufacturing, highlighting the continued importance of tactile science in industrial controls.

Summary and Strategic Implications

Tactile response defines user interaction with industrial control systems. Silicon keypads deliver durability, chemical resistance, and a customizable feel. Engineers optimize dome profiles, material properties, and surface textures to achieve reliable and comfortable actuation.

Proper tactile design enhances efficiency, reduces errors, and improves safety. Environmental stability, manufacturing precision, and quality control ensure that these keypads maintain a consistent feel over long-term use.

In modern industrial applications, touch and feel are as important as electrical performance. The science of tactile response validates design choices, supports operational efficiency, and enables safe, reliable human-machine interaction. Silicon keypads, when engineered thoughtfully, transform industrial controls into intuitive, responsive interfaces.